A cut above: Fort Worth’s Standard Meat brings meatpacking back to the Stockyards

by Bob Francis, Fort Worth Report

September 21, 2025

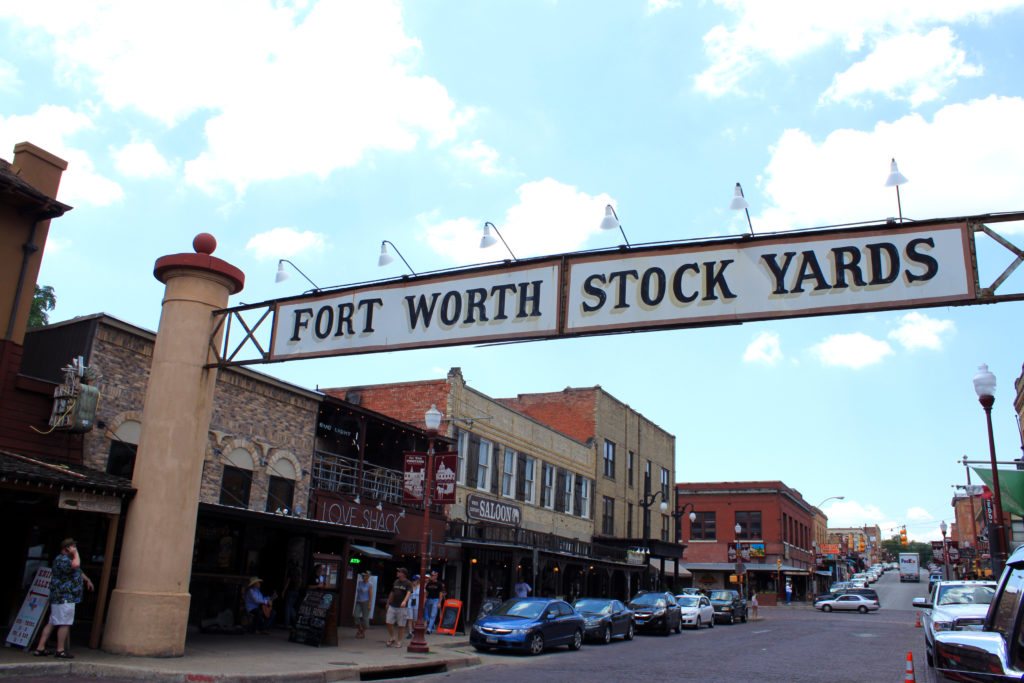

The industry that built the Fort Worth Stockyards stampeded back in a big way on Sept. 17 as local heroes Standard Meat Co. sliced the ribbon on a new 200,000-square-foot protein processing plant just down the street from where 9 million tourists visit and play cowboy annually.

Now, amid the hustle and bustle of the weekend hat-and-boot wearing crowd, new and refurbished hotels, restaurants, bars, daily cattle drives and other attractions, the very industry that created the Stockyards — meat processing — has returned.

At one time, the Fort Worth Stockyards saw Swift and Company employ more than 1,700 people, and its main competitor here, Armour, likely employed roughly the same number. In 1944, the Stockyards was reported to have processed more than $5 million worth of animals. The industry began dying after World War II as trucking and refrigeration lessened the need for centralized processing areas.

“Standard Meat Co. was founded in Fort Worth by our great-grandfather in 1935,” said Ben Rosenthal, who is CEO and co-president of Standard Meat. “With the location of our fifth plant here in the Stockyards area, we’re not just constructing a facility, we’re revitalizing a piece of our city’s industrial legacy.”

Not that anyone from that bygone era would recognize the type of meat processing going on in Standard Meat’s new plant.

They have the meat

The plant, 1101 NE 23rd St., will initially employ about 100, but is expected to quickly double and could top out at around 500 employees. It is designed with a state-of-the-art sous vide or vacuum-sealed food line. Sous vide-style cooking is gaining in popularity, as it offers evenly cooked, tender products and the vacuum-sealed packaging is said to retain a higher nutritional value.

The new plant will also supply roast beef to Arby’s, one of Standard Meat’s customers.

The plant capacity can be expanded with additional sous vide lines or other production lines as needed, said Rosenthal.

Standard Meat purchased the closed plant in 2023. Rosenthal did not say how much they spent on construction, but the Texas Department of Licensing and Regulation indicates the company expected to spend about $15 million in renovation for the 160,000-square-foot building and for adding 20,000 square feet for employee spaces.

The new plant joins the company’s others in Dallas, Irving, Saginaw and Ponder and will increase the company’s total employment to about 1,200. It is Standard Meat’s most technologically advanced to date and could ultimately produce 125 million pounds of meat annually, said Rosenthal.

“We felt like we needed to come back into Fort Worth proper and create jobs and that’s what we’re doing,” said Rosenthal during an opening ceremony for the new plant.

Standard Meat looked at land in places like Ennis and Midlothian, but then asked themselves what would be best for their employees.

“Why not come where we’re literally a two minute drive and for a lot of people that live in the Northside they can actually walk here, ride their bikes here and there’s a bus stop right over here,” he said. “This place is truly special. It’s like it was calling for us.”

While it is back in the Stockyards, it will be different from plants that were here previously and from the company’s other plants.

It will be more automated than Standard Meat’s Dallas plant that does much of the same type of work, Rosenthal said.

“We’ll be using robots to make jobs easier in this plant,” he said, not to replace workers but to help lift and move items.

Robots don’t always work, said Ashli Rosenthal Blumenfeld, co-president of the company with her brother, Ben Rosenthal.

“Some of our other attempts at using robots in our past have failed us,” she said. “Apparently, robots do not like slimy raw chicken.”

Despite the robot’s aversion to uncooked poultry, technology and innovation are key to the business’s longevity, said Rosenthal.

“Our grandfather Manny helped transform the meat business with Cryovac packaging in the ’60s,” he said. “Our dad Billy pioneered automated steak portioning techniques. Today, we’re putting our own stamp on that legacy with cutting-edge work in sous vide, cast-iron searing, portioning, meal-kit packaging, and sustainable, energy-efficient ice manufacturing.”

Standard Meat developed its ice manufacturing in response to the company’s meal-kit packaging customers. Ice manufacturers had not innovated in decades, said Rosenthal Blumenfeld.

Ice, ice baby

Inspired by food manufacturing techniques used to freeze soup, the company found an automated method of making ice packs that can be completed in just 45 minutes — far more efficiently than the conventional approach to freezing pallets of ice, which can take weeks.

“We took a piece of technology that was not ever thought of to make ice packs and did it for ice packs. We call it ‘smice,’ for Standard Meat ice,” Rosenthal Blumenfeld said.

For co-presidents and fourth-generation leaders, the plant is an extension of the family legacy and a symbol of what the organization has become under their leadership.

Since taking the reins in 2019, Rosenthal and Rosenthal Blumenfeld led Standard Meat through a period of ambitious growth — expanding from two to five facilities, rolling out next-generation capabilities and building collaborative partnerships with clients in both established industries and new market spaces.

They received recognition for that entrepreneurial spirit when the brother-and-sister duo were named EY Entrepreneur of the Year national award winners in 2024.

“We understand how to navigate uncertainty because we’ve done it before. When the world gets complicated, we get scrappy and creative. That’s the mindset we bring to our partners every day,” Rosenthal Blumfeld said.

The two siblings and co-presidents say they have learned to work together even when they might not agree on some issues.

“We might have raised voices, but we work through them fast,” said Rosenthal Blumenfeld.

A break with steak

Founded at the height of the Dust Bowl, the company has weathered war, recessions, market volatility and supply chain disruption, yet continues to grow and change with the times.

Their father, Billy, helped the company gain entree into the then-emerging chain restaurant trends in the 1970s and ’80s by cutting a deal with the parent company to Steak and Ale, Brinker International.

“We’ve continued that with our work with Outback Steakhouse,” said Rosenthal Blumentheld.

As the company has grown, she said they have begun to realize how key the company’s culture has been to their success. As a result, they are working to make sure that culture of innovation and partnerships continues even as they grow, nine decades on, she said.

Standard Meat launched a culture and strategy department that will work to embed the company’s recently renewed purpose statement — to inspire the connections and breakthroughs that ultimately feed our life — across every level of the organization, Rosenthal Blumenfeld said.

Knowing those corporate values has been key, she said, allowing the company to understand better who is a good fit.

“Once you’ve got your values, you start looking at how you hire and it is really helpful,” she said.

Key to the new plant is the employees’ space at the front of the building in a large room with plenty of natural light, said Rosenthal.

Most of the workers are in cold, refrigerated areas with little sunlight, so the break and lunch areas are open and inviting, he said.

The building also has a dedicated nursing station space for women employees equipped with comfortable chairs.

All plants also have a chiropractor that comes in on a regular basis.

“That is really popular,” Rosenthal said.

The lunchroom area is also home to a kitchen where workers may try some of the company’s products.

Rosenthal Blumfeld said investing in people is the best thing the company can do.

“Our people really set us apart from the competition,” she said.

Even the company’s logo, an “S” that is two interlocking chain links, is about connecting with people, whether it is customers, employees or family, she said.

“Our grandfather designed that to remind all of us that success is 100% contingent on connection,” she said. “It’s all about linking people together.”

As Standard Meat moves forward with its new plant, it will have another reminder about the past, Rosenthal told the crowd at the opening.

Since the new plant was formerly a meat processing facility that dates back to the 1950s, Rosenthal sought to get the plant’s previous U.S. Department of Agriculture number, the unique code for each facility that is regulated by the department.

The new Standard Meat plant in Fort Worth will receive a USDA number that the plant had in a former life. (Courtesy image | Standard Meat Co.)

This plant was the third processing facility in Fort Worth to be regulated by the USDA, its number was “3FW” and the new plant will now have that number again.

“3FW is what it’s going to be and I think that’s really, really cool,” he said.

Email Bob Francis, business editor for the Fort Worth Report, at bob.francis@fortworthreport.org.

At the Fort Worth Report, news decisions are made independently of our board members and financial supporters. Read more about our editorial independence policy here.

This article first appeared on Fort Worth Report and is republished here under a Creative Commons Attribution-NoDerivatives 4.0 International License.![]()